CMS, CLS

FAST NON-CONTACT MATERIAL CHARACTERIZATION AND PROCESS CONTROL

Emitter sheet resistance is a primary quality control parameter for silicon wafers in PV applications after emitter diffusion.

The CLS models, CLS-1A, CLS-3A, and CLS-5A, Emitter Sheet Resistance Testers allow measurement of sheet resistance at 1 to 5 points with the high throughput that meets the requirements of in-line quality control in fully automated cell production lines.

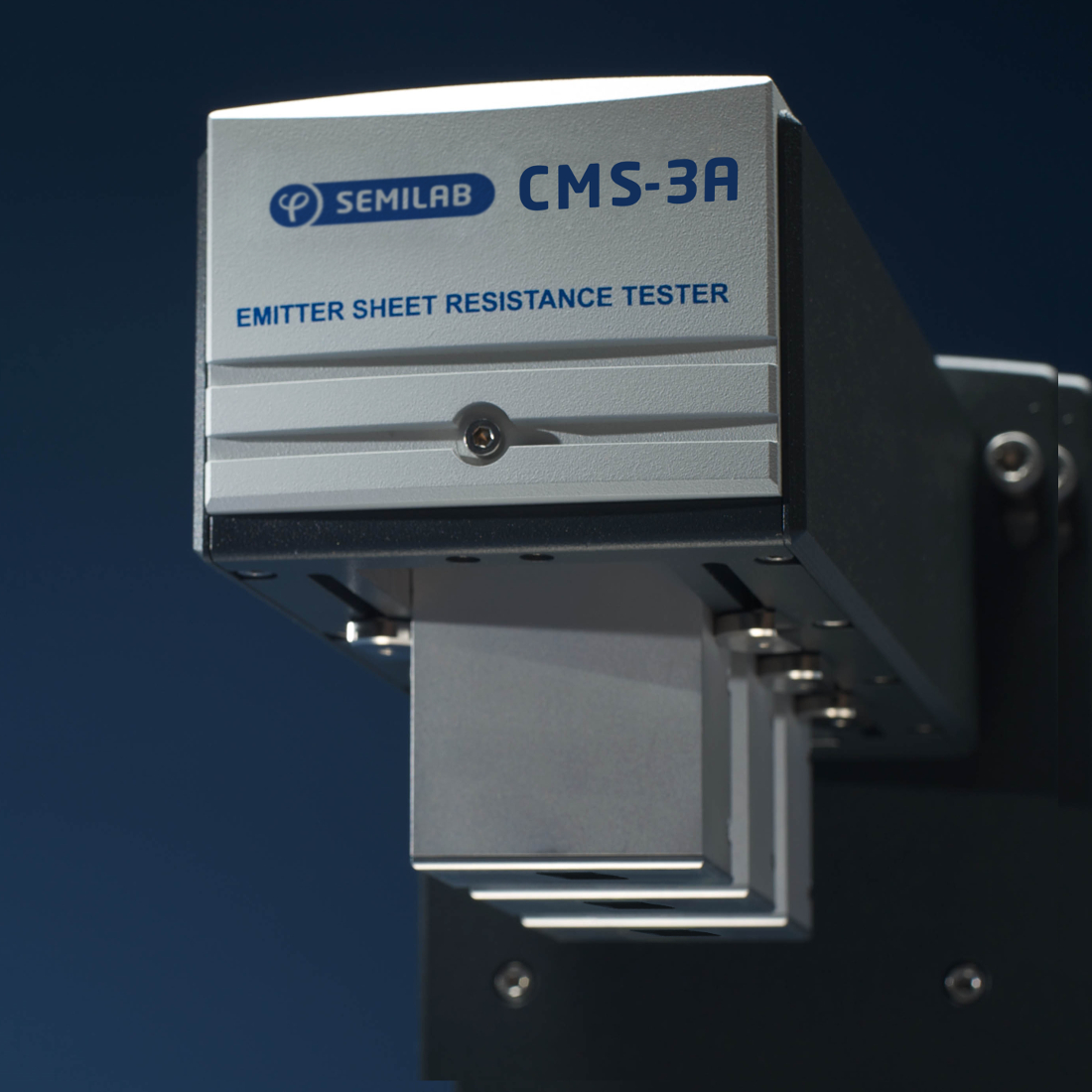

The CMS models, CMS-1A, CMS-3A, Emitter Sheet Resistance Testers allow measurement of wafers “on the fly”, i.e. conveyor belt does not stop during measurement. Therefore, they have the high throughput that meets the requirement of in-line quality control in fully automated cell production lines.

Featrues and System specifications:

- Meas. technique: non-contact, junction photovoltage (JPV)

- Sample size: 100 to 156 mm (210mm option)

- Sample structure: np or pn junctions

- Probe distance: 1.5 mm probe height above transport bel

- Sample support: on belt

- Calibration: by wafers verified with four point probe

Options:

- Measurement module (incl. 1A-5A sheet resistance measurement heads)

- Industrial PC (Windows operation system) and peripherals

- CLS-1M emitter checker – option

- Wafer presence sensor (CMS only)

Wide variety of available interfaces to automation and MES:

- 24V optically isolated I/O, Ethernet interface

- Profibus

- OPC DA

- TCP/IP protocol, content can be XML or ASCII

- SQL database

- SECS/GEM